Gas Cluster Ion Beam (GCIB) System

OVERVIEW

The GCIB system can smooth the surface of various materials, from difficult-to-machine materials such as WC and diamond to organic materials, at the sub-nanometer level.

Outline of GCIB (Gas Cluster Ion Beam) Equipment

1-1 Principle of GCIB

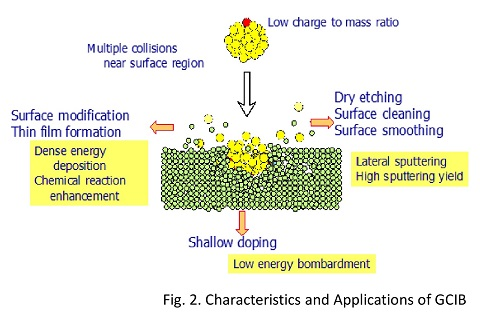

The GCIB technology is a technology for ionizing clusters of tens to tens of thousands of gas atoms, accelerating them to an energy of about 30 kV, and being irradiated to workpieces. This is a highly original technology develop by Prof. Emeritus Yamada of Kyoto University in Japan (see Figs. 1 and 2).

1-2 Effects by GCIB

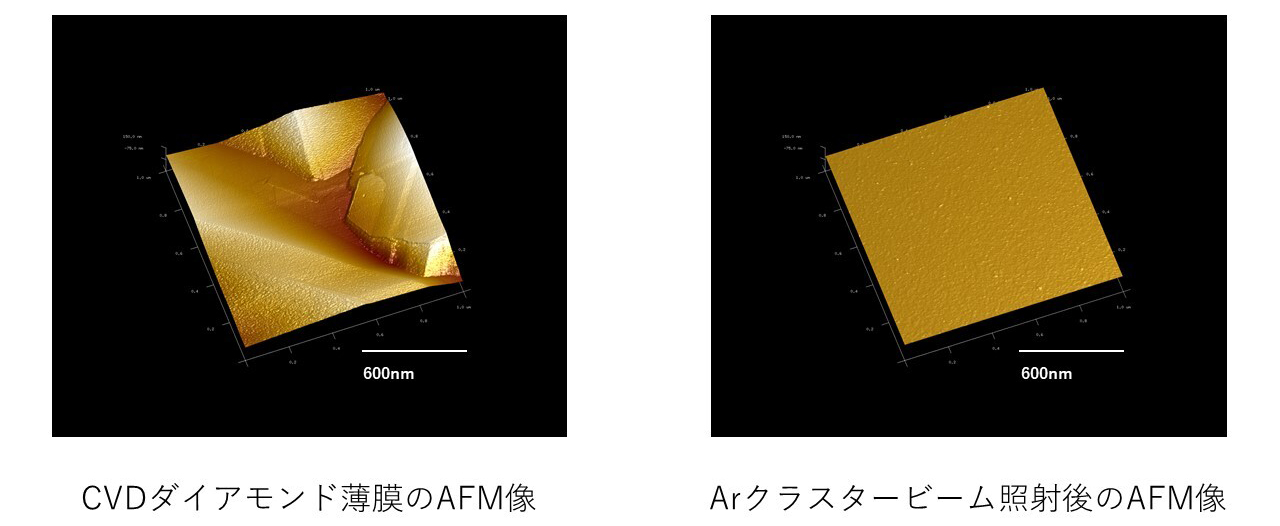

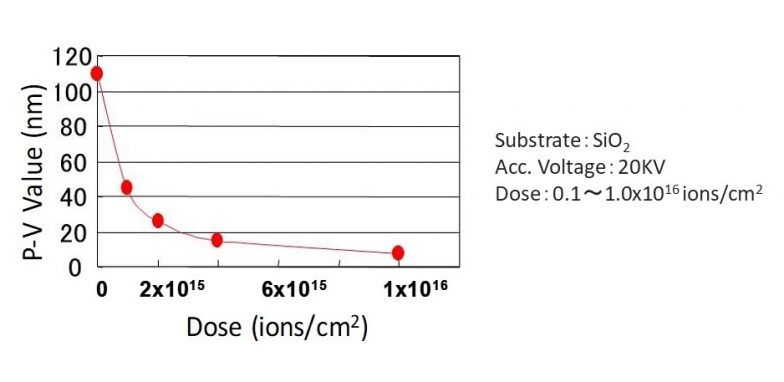

GCIB has been developed mainly in the fields of low-energy ion implantation, high-quality film formation and surface smoothing for semiconductor processes. In particular, it is extremely effective in smoothing the surface of the material that cannot be realized by other methods. Recently, it has been applied in the fields of surface smoothing of microstructures and surface modification of medical materials (see Fig. 3-5)[1].

Fig. 3. Surface smoothing of diamond thin film by lateral sputtering [1]

Fig. 4. Effect of smoothing by oblique irradiation of SF6-GCIB.

Fig. 5. Dose dependence of surface roughness during oblique irradiation of SF6-GCIB [1].

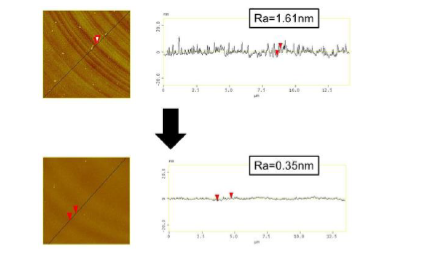

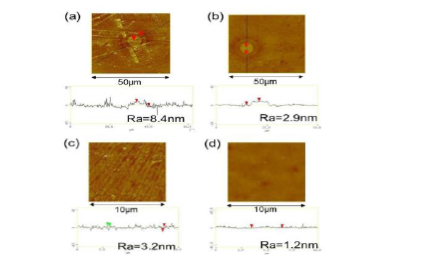

Recently, GCIB has been applied to high precision molds required for the production of small aspheric lenses used in mobile phones and small digital cameras. Fig. 6 shows an example of application to a plastic lens mold (Ni), and Fig. 7 shows that to a glass lens mold (WC (tungsten carbide)). The values of Ra (average roughness) on the surface are greatly reduced by GCIB treatment [1].

Fig.6. AFM images of plastic lens mold (Ni) surface before and after GCIB treatment (Ar-GCIB, Acc. Voltage: 20kV) [1].

Fig. 7. AFM images of glass lens mold (WC) surface. (a), (c) before and (d), (e) after irradiation. (Ar-GCIB, Acc. Voltage: 20kV) [1].

1-3 GCIB Processing Equipment

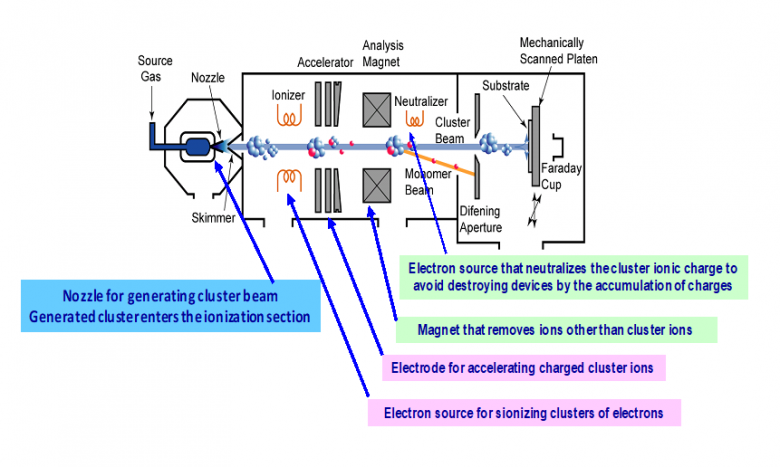

Fig.8 shows an outline of the GCIB equipment. The gas used for the gas cluster is introduced into a decompressed space through a special nozzle that is normally pressurized to several atmospheres. The gas is clustered in the nozzle, shaped by the skimmer and extracted as a beam. The neutral cluster beam is ionized by electron bombardment in the ionization section, given appropriate energy by the accelerating electrode, and irradiated to the workpiece. In the actual GCIB processing equipment, a neutralizer to prevent charge-up and a device to remove monatomic ions are attached as needed [2].

Fig.8. Outline of the GCIB equipment [2].

References

[1] I. Kataoka, I. Yamada; “Application of GCIB Technology to Optical Field”、Hikari-Gijutsu Contact, 51, 2, pp.31-38、 (2013).

[2] N. Toyoda, I. Yamada; “High-Precision Processing with Gas Cluster Ion Beams” , Journal of the Japan Society for Precision Engineering, 82, 4, pp.315-315, (2016).